WHAT IS TORSIONAL VIBRATION?

Each crankshaft has a natural frequency. If a crankshaft is held stationary at one end and a rotating load is applied to the other end, a twisting stress is created in the crankshaft. If the rotating load is released, the crankshaft springs back past its at-rest position and a twisting stress is briefly present in the opposite direction.

The crankshaft again springs back past its at-rest position. This oscillation continues, in reducing amounts, until the crankshaft stops oscillating. The rate of the oscillation is referred to as the crankshaft’s natural frequency.

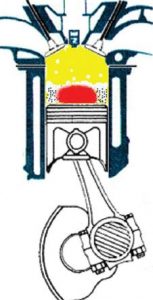

In the engine, each power impulse imparts a torque, or rotating force to the crankshaft. Because one end of the crankshaft resists this rotation, full-power torque impulses can overcome the inherent stiffness of the crankshaft, causing it to twist. As the power pulse ceases, the crankshaft springs back in the opposite direction to “undo” the twist. It springs back past its at-rest position and a twisting stress or torsion is briefly present in the opposite direction.